Double-Sided Kapton Tape Ultimate Guide: Creative Applications with Custom-Colored Release Liners

Share

If you've ever struggled with component fixation and insulation protection during electronics manufacturing, double-sided Kapton tape might be the solution you're looking for. This heat-resistant double-sided adhesive material not only withstands the extreme temperatures of SMT reflow soldering but can also significantly improve production efficiency through custom-colored release liners—a practical feature many businesses have yet to fully utilize.

What is Double-Sided Kapton Tape?

Double-sided Kapton tape (polyimide double-sided tape) uses polyimide film as the base material, coated on both sides with high-performance silicone adhesive and laminated with PET fluoroplastic release film. Its most notable characteristic is the ability to withstand extreme high temperatures (long-term use up to 260°C) while providing excellent electrical insulation properties.

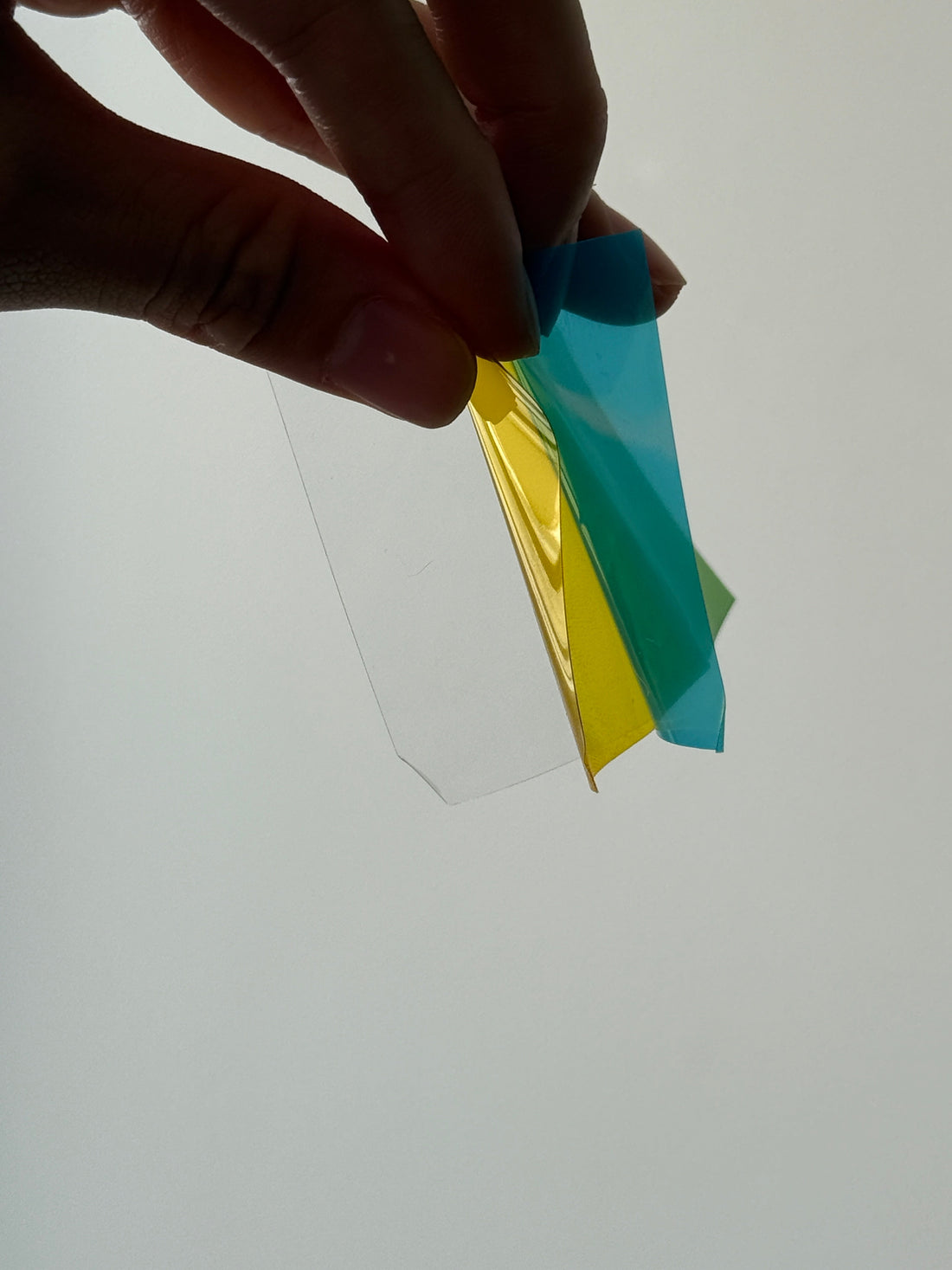

Custom-colored release liners are a practical feature of double-sided Kapton tape. By equipping the two sides of the tape with different colored release liners (such as amber, tea color, black, or golden yellow), you can easily distinguish the front from the back on the production line, reducing operational errors. This is particularly useful in automated production environments and complex assembly processes.

Unique Advantages of Double-Sided Kapton Tape

-

Exceptional High-Temperature Performance: Withstands long-term working temperatures from -60°C to +260°C, with even higher short-term tolerance.

-

Excellent Electrical Insulation: High dielectric strength, suitable for high-voltage and high-frequency environments.

-

Strong Chemical Resistance: Resists solvents, acids, and alkalis, remaining stable in harsh environments.

-

Flexible yet Tough: High tensile strength while maintaining good flexibility.

-

Customized Release Liners: Both sides can have different colored release liners, improving production efficiency and reducing errors.

How to Choose the Right Double-Sided Kapton Tape for Your Project

1. Determine Thickness Requirements

Double-sided Kapton tape is typically available in various thicknesses from 0.04mm to 0.2mm. Thinner specifications (like 0.04mm) are suitable for high-precision electronic assembly, while thicker versions offer better cushioning and ability to fill uneven surfaces.

2. Select Release Liner Color Combinations

When customizing release liner colors, consider these combinations:

-

Red/Blue Combination: The most easily distinguishable contrasting colors, ideal for quick identification.

-

Amber/Clear: Traditional choice, suitable for most general purposes.

-

Black/Golden Yellow: Professional appearance, perfect for high-end products.

3. Evaluate Adhesive Characteristics

Ensure the selected tape can be cleanly peeled after high-temperature exposure without residue, which is crucial for rework and repairs.

Creative Application Scenarios for Double-Sided Kapton Tape

Electronics Manufacturing Field

-

Flexible Circuit Board Production: Used as insulation and fixation material in FPC rigid-flex boards.

-

SMT Reflow Soldering: Securing flexible circuit boards to fixtures, withstanding reflow soldering temperatures.

-

High-Temperature Component Bonding: Fixing electronic components in high-temperature environments.

-

Connector Placement: Applied on connectors for pick-and-place machine handling, replacing metal plates.

Innovative Application Fields

-

Lithium Battery Assembly: Used for insulation and fixation between battery cells, heat-resistant and safe.

-

LED Lighting: Securing LED strips while providing necessary insulation.

-

Automotive Electronics: Securing wiring harnesses and sensors in high-temperature environments like engine compartments.

-

Aerospace: Used for fixation and insulation in electronic systems under extreme temperature conditions.

Professional Tips for Using Double-Sided Kapton Tape

Surface Pre-treatment

-

Ensure bonding surfaces are clean, dry, and free of oils.

-

Wipe surfaces with isopropyl alcohol for optimal adhesion.

-

Consider surface treatment for low-surface-energy materials.

Application Techniques

-

First, remove one side's release liner (e.g., the red side) and apply it to the first surface.

-

Apply pressure to ensure full contact between the tape and the surface.

-

Remove the other side's release liner (e.g., the blue side).

-

Precisely align the second component and place it gently.

-

Apply pressure from the center outward to eliminate air bubbles.

Removal Techniques

-

Peel off slowly and steadily at a 180-degree angle at room temperature.

-

If difficult, use a heat gun to warm slightly (but do not exceed the tape's temperature limit).

-

Use specialized solvent to clean any residual adhesive.