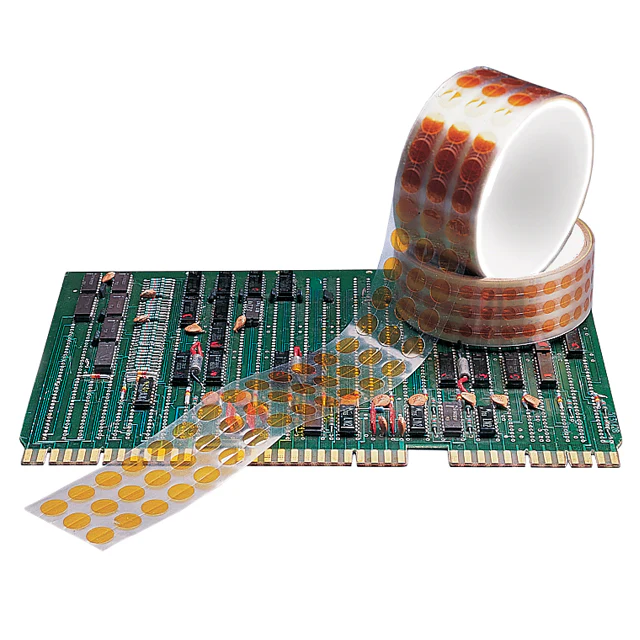

Die-Cut Polyimide Tape for IC Packaging – Precision & Protection

Share

Die-cut polyimide tape (also known as Kapton tape) is a high-performance, heat-resistant adhesive material that has been precision-cut into custom shapes for specialized applications in semiconductor packaging and IC manufacturing. With its exceptional thermal stability (up to 260°C), electrical insulation, and chemical resistance, it plays a vital role in protecting delicate components during wire bonding, encapsulation, and thermal processing.

In IC packaging, die-cut polyimide tape is used for:

✔ Wafer dicing protection – Shields silicon wafers from contamination during cutting.

✔ Wire bonding isolation – Prevents short circuits between fine-pitch bond wires.

✔ Encapsulation masking – Defines precise areas for epoxy molding compounds (EMC).

✔ Lid attach & heat spreader bonding** – Ensures secure thermal interface material (TIM) application.

Key Benefits of Die-Cut Polyimide Tape in IC Packaging

1️⃣ Extreme Heat Resistance for High-Temp Processes

- Withstands **260°C+ temperatures, making it ideal for lead-free soldering, curing, and reflow processes.

- Unlike PVC or PET tapes, it won’t melt or leave residue, ensuring clean post-processing removal.

2️⃣ Precision Die-Cutting for Miniaturized IC Designs

- Laser-cut into exact shapes (gaskets, frames, spacers) for tight-tolerance packaging needs.

- Critical for fan-out wafer-level packaging (FOWLP) and 3D IC stacking.

3️⃣ Superior Electrical Insulation & ESD Protection

- Low-static properties prevent electrostatic discharge (ESD) damage to sensitive ICs.

- Dielectric strength (5,000V+) isolates high-voltage components in power ICs.

4️⃣ Chemical & Moisture Resistance for Reliability

- Resists flux, solvents, and cleaning agents used in post-packaging processes.

- Unlike paper tapes, it won’t absorb moisture, preventing corrosion in humid environments.

---

Top Applications in IC Packaging

✔ Wafer Backside Protection – Guards against scratches during grinding and handling.

✔ BGA & CSP Substrate Masking – Defines solder ball placement areas.

✔ EMC Dam Formation – Creates barriers for precise epoxy encapsulation.

✔ Thermal Interface Bonding – Secures heat spreaders in advanced packaging.

- "Best die-cut polyimide tape for IC packaging"

- "Kapton tape vs PET for semiconductor masking"

- "How to use precision-cut tape in wafer dicing"

- "High-temp adhesive solutions for 3D IC stacking"

- "Where to buy custom die-cut Kapton tape"