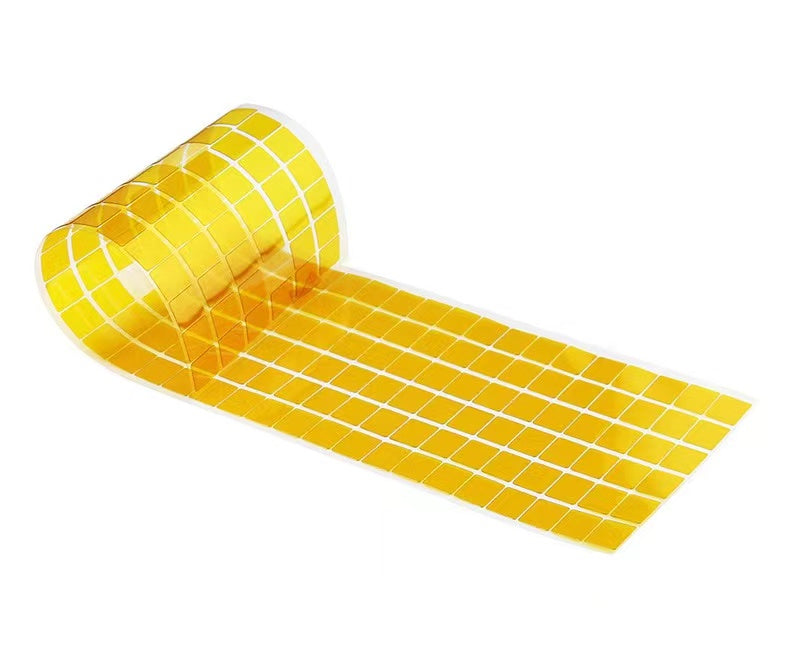

Die-Cut Polyimide Tape: Precision Kapton Solutions for Electronics

Share

What is Die-Cut Polyimide Tape?

Polyimide tape (commonly known as Kapton tape) is a high-performance material renowned for its extreme heat resistance, electrical insulation, and chemical stability. When precision die-cut into custom shapes, it becomes an indispensable solution for electronics, aerospace, automotive, and industrial applications.

Die-cutting allows manufacturers to create complex adhesive components with tight tolerances, ensuring perfect fit and functionality in specialized environments.

Key Advantages of Die-Cut Polyimide Tape

1️⃣ Custom Shapes for Precision Applications

Laser or die-cut into exact dimensions (gaskets, insulators, spacers).

Ideal for PCB shielding, flexible circuits, and coil insulation.

2️⃣ High-Temperature Resistance (Up to 260°C / 500°F)

Withstands soldering, reflow, and thermal cycling without degrading.

Protects sensitive components in automotive, aerospace, and LED lighting.

3️⃣ Superior Electrical Insulation

Dielectric strength prevents short circuits in high-voltage applications.

Used in battery insulation, motor windings, and EV components.

4️⃣ Chemical & Abrasion Resistance

Resists solvents, oils, and acids—unlike standard tapes.

Maintains adhesion in harsh environments (industrial machinery, oil & gas).

Top Applications of Die-Cut Polyimide Tape

✔ Electronics:

Flexible PCB stiffeners – Reinforces thin circuits.

EMI/RFI shielding – Custom masks for sensitive components.

✔ Automotive & Aerospace:

Wire harness insulation – Prevents heat damage in engines.

Sensor protection – Precision-cut for tight spaces.

✔ Medical Devices:

Sterilizable adhesives – Withstands autoclaving.

Wearable tech – Thin, flexible, and biocompatible.

✔ Energy & Industrial:

Solar panel edge sealing – UV-resistant barriers.

Transformer insulation – High-voltage safety.